i awhile back i asked what posting was, well i found an article on www.homemadeturbo.com

Block Posting

Block posting, this is an alternitive for those lame ass block guards, and for people that cannot afford to sleeve there blocks. Posting and Pinning has been around for several years. It is used in Nascar and other forms of racing. Larry (theoldone) uses this on lots of his Honda engines he builds, and he actually did my built ZC w/ pins. I figured this time I could do it myself, since it didnt look to hard.

First starting off with some pins/posts. Basically there are little threaded studs, that are made up of the exact same alloy as the honda/acura aluminum block. This is so when the block heats up and cools down. The studs will do the exact same. I got this set of 12 studs from (endyn) for 35 bucks.

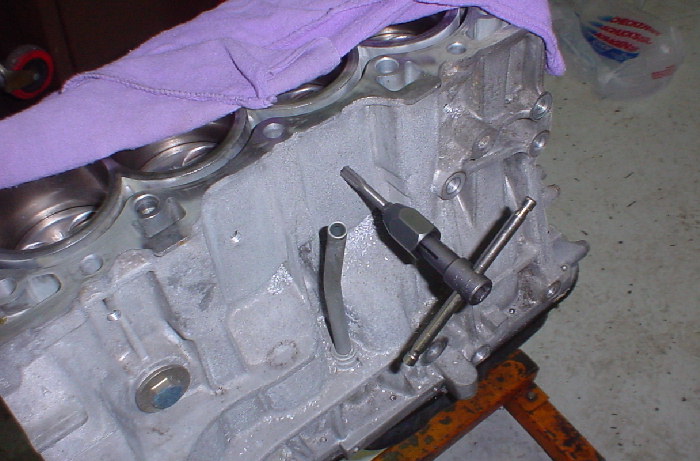

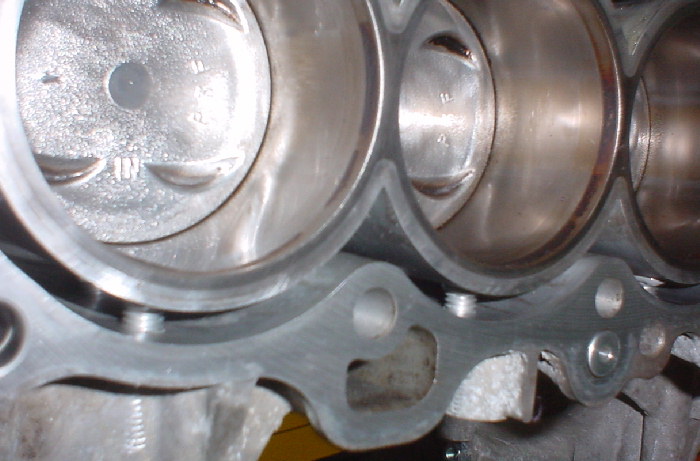

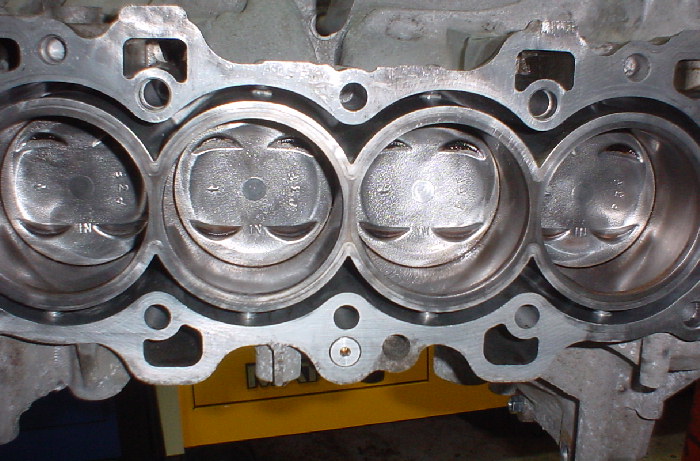

Drilling 4 holes in the center of each sleeve about 3/8 of the way down (from the top). Why not put these pins at the top of the cylinders? well, all cracks in sleeves normally start midway up.

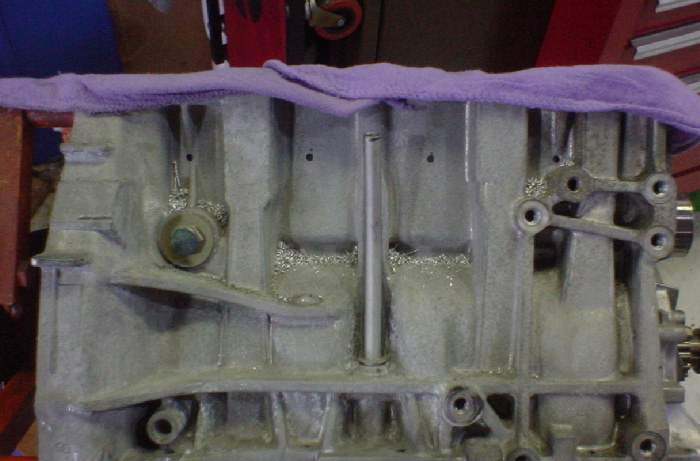

Then threading the holes in the block with a tap. You will need 2 taps for this, since the main cut tap with the tapper will hit the sleeve real quick, then you will need another tap that has the end cut off, so you can get threads all the way through the outter block

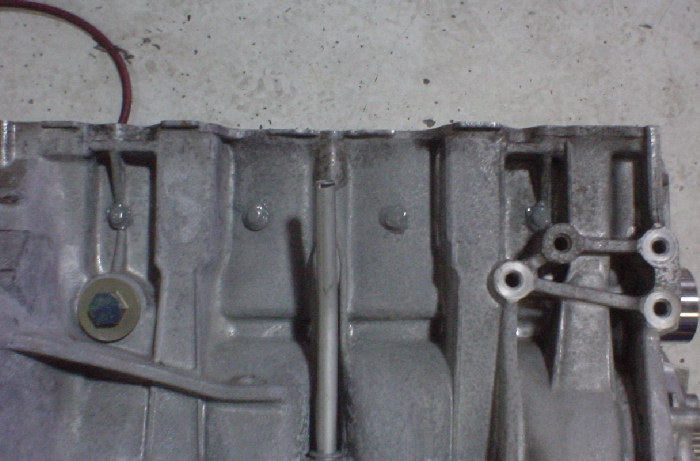

This is the intake side, we use 2 pins per cylinder, Larry claims he has found the thrust axis points on these blocks, thus the intake side having more load, and using 2 pins insted of one. This makes it kind of a bitch, because there really isnt the best spots for this. I kinda went wherever the **** I wanted, anywhere that was flat. I really didnt feel like cutting the webbing off the block to make it absoultly perfect.

The pins are torqued to 2inch pounds.... YES 2 inch pounds, that's like hardly anything. Anything more could distort the sleeves. Be sure that the area around the pin hole is really clean, then I applied JB weld on the threads and all over the stud so it would stay in place. Larry says its not a good idea, but I think he said this just so Endyn wouldnt look bad "ya use JB WELD" LOL.. He recommend using the Devcon liquid Aluminum stuff. I think JB will work just fine. (we will find out soon enough)

Be sure to clean out all the metal shavings really well, and let the epoxy sit up for atleast a day before you install the engine.

Reply With Quote

Reply With Quote

Bookmarks