Hey guys,

Thought I would start this thread after speaking to a number of Qld boys and seeing that many people don't know the dangers when buying aftermarket Alloy Lug Nuts for their wheels.

We all consider the basic things when buying a lug nut:

- Thread width

- Thread pitch

Sure we think this is all to take in to account (me included originally) but there are other issues that you need to consider when buying these Alloy Nuts.

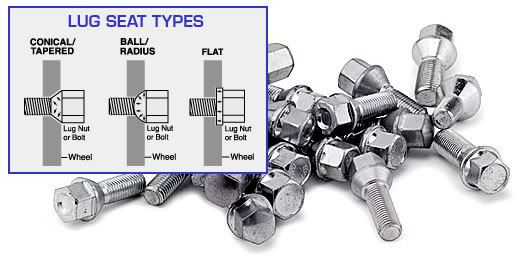

1. Oem wheels and Aftermaket Alloy Lug nuts: The "Seating" face. Honda Oem wheels have a 'bowled' (Acorn) ball seating face and by looking at your Oem wheel nuts you can observe this. (see photo below) See how the chrome oem nut, seat face is 'curved'. Next to it is a aftermarket Alloy nut. See how its mating face is chamfered, not curved, but straight. You can also see on this aftermarket item the affects when using it mated against a Oem curved seated wheel (see the wear mark around the top). As you can see, because of the mis-match of mating surfaces the whole surface area is focused along 1 point around the nut. "So?" you may think? Well instead of the whole load being distributed across the 'whole' 100% mating surface. You are now distributing the load over at a guess 10% or less of the area and it will astronomically multiply in load at that point. The dangers speak for themselves. These Nuts were not designed for this focused load and can and may fail.

This is the nuts I had on my ITR oem wheels. ie. not good.

2. Aftermarket Alloy Lug nuts and Wheel Studs: Another thing we all do is chuch these Alloy nuts on without considering the strength difference between Alloy nuts Vs Oem Steel nuts. Sure they are "forged" alloy, but they will never be as strong as Oem 'given the same length of thread'. So therefore it is extreemly recomended to purchase "Extended Wheel Studs" for these Alloy nuts. This will give them extra thread to bite on to. Skunk2 recomends the use of extended wheel studs when using their Alloy Nuts as I am sure a lot of other top companies would. And a tip, don't use an air gun to tighten up your nuts, use a manual brace.

These are the different types off seats, Ball (OEM wheel), Conical (aftermarket wheel)

This Checklist is what we SHOULD consider when buying Alloy Lug nuts:

Thread size

Thread pitch

Mating surface profile (make sure your lug nuts are matching to your wheels)

Extended wheel studs (install these when using Alloy lug nuts)

Torquing the lug nuts (Use a manual hand wheel brace, not a air gun)

Buy a brand name quality product (No substitute for quality)

To sum up. Sure these aftermarket lug nuts are cool, light and a cheap addition to your car. But we really need to take in the consequences of just throwing them on our cars. It is a big safety issue which I don't think is that well known out there. I hope this write up thread provides some information to everyone on the dangers that can be involved with a what we think is 'just a simple/straight forward mod'.

Please, if there is any other info you wish me to add to this post, discuss away and I will endeavor to keep it up to date.

Additional Reference:

http://customwheelsmarket.com/wheelinkit.html

Reply With Quote

Reply With Quote

Bookmarks