|

-

Originally Posted by JohnL

No worries.

Thanks mate

Originally Posted by JohnL

Sorry to be pedantic, but it's not really a modification as such, it's returning the TPS to it's correct stock condition, so it's more like 'tuning'.

I think it would be better to say 'can be' rather than 'is', because the effectiveness will vary according to how far the calibration has driffted over time.

Out of curiosity, how far out were your voltages before you 'tuned' them? Also, when you rotated the TPS, did you move the WOT voltage off spec in order to achieve the correct closed throttle spec? If 'yes' then you might want to consider returning the WOT voltage to spec and resetting the closed throttle to spec using the throttle stop screw.

True true,I always get excited when I come accross a good find

Mine was 0.42,so a significant improvement.

I set mine at 0.51 for 1 week,put it back to 0.48 and damn,BIG difference!

I pretty sure my throttle stop screw is welded on.I know what you are saying and I will add it to the thread.Thanks so much John!!

Originally Posted by JohnL

While checking around to verify whether your quoted voltages applied to my Accord, I saw a couple of references to the stock TPS "rivets" actually being blind headed bolts threaded into the TB casting (so can't be undone with 'normal' tools, Honda obviously doesn't want anyone messing with the TPS setting). So if this is correct there should have been no need to grind the head off, just cut a screwdriver slot...

It is a screw but I couldn't see you being able to cut a slot in the top without the top of the rivet falling apart.Prove me wrong

-

Originally Posted by JohnL

75$? You're using fully synthetic aren't you? A good synthetic should last longer than a good mineral based oil, so IMO you're really throwing money away. If you're going to change the oil every 5000km you might as well use a good mineral oil.

What you seem to be doing might be reasonable insurance for a very high performance / stressed / high $ build engine, but not otherwise, really.

I know what your saying.Maybe I just like to think my d16y4 is a high performance machine

Originally Posted by JohnL

Then I'll bet you got a dose (or doses) of dirty fuel somewhere / sometime before the changeover. I've changed a fuel filter that had at least 100,000km on it, and seen no performance change, not that I really expected there to be one since the filter had passed a flow test with flying colours (I just felt I should change it 'just in case' and that it was so old).

Be careful of placebo affects too. I'll swear that my car goes harder and even handles better after I've cleaned it..

It suprises me! I mean I've cleaned the injectors,fuel tank but still a noticeable difference...

Yes,I learnt about placebo effect

Originally Posted by JohnL

Use 91 if that's the fuel specified by Honda for your engine (and you haven't increased the CR or supercharged it). Without being able to make any categorical statement, I suspect your problem above to be either coincidental with some other problem, and / or maybe you have had some bad 91 octane fuel.

You should always try to buy fuel from a high turnover outlet as fuel that's been sitting in the servo's tanks too long can go stale and lose octane rating along with some of the properties that make it ignite readily in the combustion chamber..

Forsure forsure.All my problems are fixed now,OMG,can't believe I'm saying that  My car is going 100%!! My car is going 100%!!

Originally Posted by JohnL

Advancing the ignition timing on speculation is potentially dangerous because you may get what is in effect pre-ignition, which can cause damage (the dyno will tell you what's what...). If you do this I suspect the ECU may well 'retard' the timing back to stock in any case, unless you advance the base timing so far it's beyond the ECUs parameters to correct..

Definately.Retarding dosen't seem a problem though as mine was retarded 10 degrees for 1 year and 9 months!!!!

Originally Posted by JohnL

Many things (very many, and not just to do with cars...) seem to be 'common sense' or "logical", but in reality are incorrect assumptions. Cooler fuel may be very slightly denser, so the mixture may be very slightly richer with a cooler fuel, which may or may not be a good thing. Cooler fuel may very slightly lower the temperature of the inducted air, cooling it ever so slightly more as the fuel is injected resulting in a very slightly greater quantity of air being inducted, but at best it will be a miniscule difference...

I tried this when karting, i.e. chilling the fuel in an esky and using an insulated tank and lines on the kart. Never made a jot of difference as far as I could tell, and didn't show up on the stop watch either...

Wow,you are full of Knowledge John

-

Originally Posted by beeza

Mine was 0.42,so a significant improvement.

I set mine at 0.51 for 1 week,put it back to 0.48 and damn,BIG difference!

I'm quite happy with mine at 0.5v, very significantly better than it was at 0.44v. From what I can gather on the net, 0.5v does seem to be the most commonly quoted CT voltage. Where did you get your 0.48v - 0.49v figure?

Originally Posted by beeza

I pretty sure my throttle stop screw is welded on.I know what you are saying and I will add it to the thread.Thanks so much John!!

If it's the same as the Accord TS, then there will be a lock nut underneath the TB casting. I didn't manage to get a screwdriver to turn the TS screw (awkward with having to come at the TS screw vertically from underneath, with shit in the way, and I couldn't really see anything without removing the TB which I wanted to avoid), but after loosening the locknut (easy) I could turn the TS screw from the top using pliers.

Originally Posted by beeza

It is a screw but I couldn't see you being able to cut a slot in the top without the top of the rivet falling apart.Prove me wrong

Cut a shallow slot in the fastener head with a hack saw, it'll be fine...

-

Originally Posted by beeza

Wow,you are full of Knowledge John

I have been told that I'm "full of it..."

-

Originally Posted by JohnL

I'm quite happy with mine at 0.5v, very significantly better than it was at 0.44v. From what I can gather on the net, 0.5v does seem to be the most commonly quoted CT voltage. Where did you get your 0.48v - 0.49v figure?

I think from Honda-tech.Do what I did,try it at 0.48 after a week or so and see if there's a difference

Originally Posted by JohnL

If it's the same as the Accord TS, then there will be a lock nut underneath the TB casting. I didn't manage to get a screwdriver to turn the TS screw (awkward with having to come at the TS screw vertically from underneath, with shit in the way, and I couldn't really see anything without removing the TB which I wanted to avoid), but after loosening the locknut (easy) I could turn the TS screw from the top using pliers.

I'll check mine.

Cut a shallow slot in the fastener head with a hack saw, it'll be fine...[/QUOTE]

-

Originally Posted by JohnL

I have been told that I'm "full of it..."

Haha,me too

-

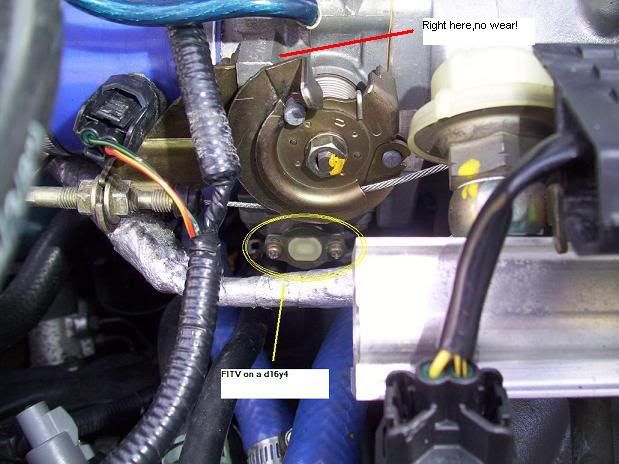

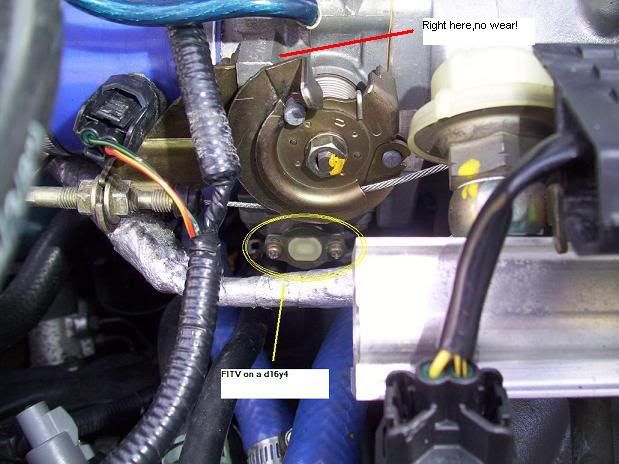

The y4 dosen't have a screw just solid metal,so no adjustment needed:

(Don't worry about the bottom bit)

-

whats all this to do with increasing response ?

-

Because Calibrating the Voltage on the Tps Sensor will achieve this,to a degree,but it will make a nice difference to throtle response,acceleration etc etc etc,heaps of things.

A must do.

-

Originally Posted by beeza

The y4 dosen't have a screw just solid metal,so no adjustment needed

It doesn't necessarily mean that no TS adjustment is ever needed, just that it may not be so easy when it is (?).

The Accord TS set up (with the adjustable threaded TS screw installed in the TB) is "solid metal" too, but over deep time the contacting points (steel to steel) obviously wear slightly (it doesn't seem to take much wear at all to cause a significant closed throttle voltage change, so it's good that wear will be very slow to occur).

If the y4 TS is steel contacting against the softer aluminium of the TB casting, then the aluminium contact point might wear faster than the Accord's steel on steel TS contacts (but I'm not sure, it would depend on the size of the contacting area). There may be a 'tab' on the cable pulley / wheel that can be 'tweaked' in order to adjust the TS...? It might also ber possible to adjust it by say gluing some metal shim onto the contact point???

Adjustment to the TS will only be needed if the TPS closed throttle (CT) voltage is off spec. If the WOT voltage is off spec then the the TPS rotational position needs adjusting (as per beeza's 'how-to').

So:

If only the CT voltage is off spec, then only the TS needs adjusting.

If only the WOT voltage is off spec, then the TPS itself needs to be rotated to bring the WOT voltage back into spec, and the CT voltage must then be re-adjusted using the TS.

If both the WOT and CT voltages are off spec, then the TPS needs to be rotated until either both the WOT and CT voltages are within spec, or, the WOT is within spec and the CT then adjusted using the TS.

In all cases the TS should only be used to adjust the CT TPS voltage and NOT the idle speed. Any adjustment to idle speed should be by means of the idle speed screw.

-

Originally Posted by bennjamin

whats all this to do with increasing response ?

Because if the TPS CT voltage is off spec then the light throttle / low rpm torque will be adversely affected and the engine will be lacking in immediate response to lighter throttle inputs (and you spend 99% of the time at light throttle openings). This adversely affects the drivabilty of the car, and probably fuel economy as well.

Lack of low rpm torque is especially noticable when taking off from rest, requiring more care / skill with balancing of the throttle input and clutch slippage because the engine is in greater danger of stalling.

You might think that if light throttle torque is poor then why not just open the throttle more, but this doesn't really work so well for 'normal' driving (you can get the same affect, but the engine feels like it's working a lot harder to achieve it). Having the TPS correctly calibrated can make the car much nicer to drive, particularly in traffic / around town.

-

Originally Posted by JohnL

It doesn't necessarily mean that no TS adjustment is ever needed, just that it may not be so easy when it is (?).

The Accord TS set up (with the adjustable threaded TS screw installed in the TB) is "solid metal" too, but over deep time the contacting points (steel to steel) obviously wear slightly (it doesn't seem to take much wear at all to cause a significant closed throttle voltage change, so it's good that wear will be very slow to occur).

If the y4 TS is steel contacting against the softer aluminium of the TB casting, then the aluminium contact point might wear faster than the Accord's steel on steel TS contacts (but I'm not sure, it would depend on the size of the contacting area). There may be a 'tab' on the cable pulley / wheel that can be 'tweaked' in order to adjust the TS...? It might also ber possible to adjust it by say gluing some metal shim onto the contact point???

Adjustment to the TS will only be needed if the TPS closed throttle (CT) voltage is off spec. If the WOT voltage is off spec then the the TPS rotational position needs adjusting (as per beeza's 'how-to').

So:

If only the CT voltage is off spec, then only the TS needs adjusting.

If only the WOT voltage is off spec, then the TPS itself needs to be rotated to bring the WOT voltage back into spec, and the CT voltage must then be re-adjusted using the TS.

If both the WOT and CT voltages are off spec, then the TPS needs to be rotated until either both the WOT and CT voltages are within spec, or, the WOT is within spec and the CT then adjusted using the TS.

In all cases the TS should only be used to adjust the CT TPS voltage and NOT the idle speed. Any adjustment to idle speed should be by means of the idle speed screw.

Gotcha John!

I'll summerise the above into the Tps thread,thanks heaps mate,this fills a void that was forming in my mind.

There is slight wear on the metal contact point,it's slight but it's there,I'll get a pic up soon

If the wear was bigger you could glue/weld a bit of metal on there.Maybe you could just give the aluminum part on the TB (that holds the accelerator cable) a little tweak with some pliers.Just 'bend' it ever so slightly?

I'll check my accelerator cable for some adjustment 'tab'

I realise now I need to include adjustment of the accelerator cable in the DIY cause if there's slack there it sucks

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

Reply With Quote

Reply With Quote My car is going 100%!!

My car is going 100%!!

Bookmarks