|

-

Calibrating the Voltage on the TPS Calibrating the Voltage on the TPS

Disclaimer: The following is provided as a GUIDE ONLY, and neither myself nor Ozhonda take any responsibility for the outcomes of someone else doing the following. You follow these steps at your own risk!

Any additional/relevant information gained from this thread has been added to the first 2 posts.So all the info you need is in the first 2 posts.No need to look through the thread for any additional information.

Aim:

To calibrate the voltage on the TPS Sensor,a sensor on the throttle body that tells the ECU where the throttle is positioned.Over time the Tps goes out of calibration and your car's performance suffers greatly for it.

I was VERY impressed with the difference this made to my car.It increased throttle response,smoothly revving across the whole rev range and makes for a far enjoyable car to drive.

If your car is around the 8 year old mark,you should DEFINATELY do this IF you want better performance from your car and offcoarse,who dosen't?!

Again,I can't emphasize how effective this is,a must do!

Combined with modifying ya stock TB,your car won't be the same and you'll NEVER wanna go back to stock again!

So do em' both eh!

Modifying the stock TB for more airflow

EK1 Civic has just done this,this is what he said after it:

Originally Posted by EK1 Civic

The car runs so different now, i have to use the pedal less, the responce is amazing, even when i put the foot down it goes even harder then before. I tested going up a hill to see for improvement, basically went in gear 3, 42kms at about 1700 revs and it held it the whole time without having to push the pedal any further. Feels like my lil civic has been reborned. Amazing DIY props to u beeza

THE TPS IS OVERLOOKED OR SHOULD I SAY NOT UNDERSTOOD BUT THE TPS HOLDS GREAT BENEFITS WHEN CALIBRATED.

Required:

Hacksaw

Suburu Upper Engine Cleaner/Super Engine Conditioner

Screwdrivers

2 screws 16mm x 5mm Metric thread with a dome head

2 pins

Multimeter

Allen Key (maybe needed for the Throttle stop screw)

Small socket and ratchet

This can be performed by yourself,without help,no problem.

This is being done on a d16y4.

The screws you need are 16mm long and 5mm wide,metric thread,with a dome head.Definately both d and b series engines use this screw.

16x5 Metric thread with a dome head:

Steps:

Remove the Throttle body -

4 bolts

3 sensors that just unplug (TPS,Map and IACV)

2 coolant hoses on the bottom,unclip the metal clamp and pull the hose off.A little coolant will run out,perfectly fine.If you don't want to loose the coolant,plug the hoses up.

Accelerator cable (and gearbox cable if an automatic)

Give it a clean:

If your tps is riveted on,U can hacksaw them off,dont need a grinder OR U can cut a line/groove down the middle for the screwdriver then remove it and re-use it:

Use a screwdriver to tap the thread left in there out:

There She blows!

The Tps gasket is torn but it wont matter at all,so I will re-use it:

Now,clean the whole Throttle body up,I only use Suburu Upper engine cleaner to clean with now OR another product which I reckon is subi upper engine cleaner in another bottle is 'Engine conditioner',it's a Japanese product,i.e Japanese writing on the bottle and it's brilliant.Carby cleaner is crap.

Map Sensor:

Intake Air Control Valve (IACV),Clean that up real good!

Let it all dry out:

Time to get them screws!

IMPORTANT: When U put it back together,make sure that little plastic doova on the tps goes between those 2 metal bits.

Put it all back together:

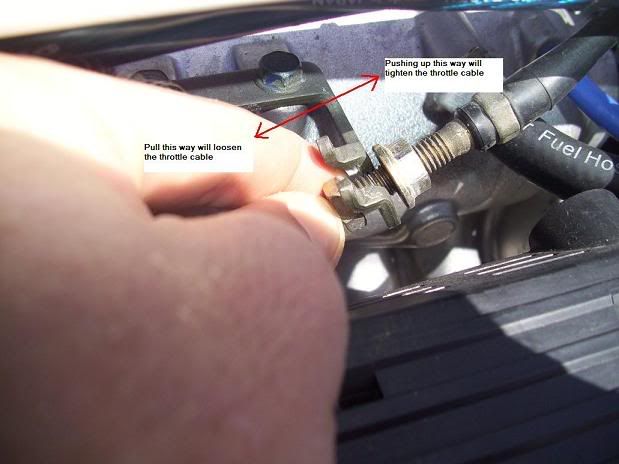

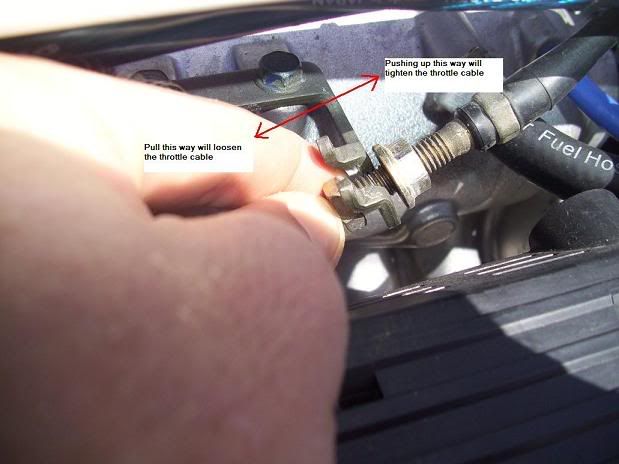

Next,is to adjust the throttle cable..This is done by undoing these 2 nuts and tensioning the cable:

At Closed Throttle (CT) the cable needs to be firm but not tight.At Wide Open Throttle (WOT) when the pedal hits the floor should be the same time as the Throttle body Wide Open Throttle stop (WOT) is contacted,therefore there is no significant load on the cable nor the WOT stop:

The WOT stop varies in design but the exact same principle.I know on the b18c it's on the bottom.

The easiest way to achieve this is to put your foot to the floor (WOT) and check the above.If there is a gap,the cable needs to be tensioned to close the gap.If the TB WOT stop is contacted before the pedal hits the floor,you need to loosen the cable off a bit.

Here's a VIDEO of the end result.A nice firm cable.When the accelerator pedal makes contact with the floor,is the same time the TB WOT stop is contacted,Beautiful!:

OK.Now the fun part.On the TPS sensor,there are 3 wires - Yellow,red and green (all with a black stripe)

Red is Positive and Green is Negative.

I inserted the pin through the wire but I have learnt that the better way to save damaging the wire is to stick the pin up into the plug where the wire connects to the plug,as so:

Last edited by beeza; 05-03-2012 at 08:07 AM.

Tags for this Thread

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

Reply With Quote

Reply With Quote

Bookmarks