|

-

Doing the rings myself? what you think?

Ok so i went to go pick up my civic from the tuners today and was told that my rings need replacing before taking it anywhere close to 20psi

Only rebuilt my motor roughly 20 thou ago. The previous tune must have chewed them up over a year. So i mean i've stopped mechanics working on my car for over 3 years now. I've done everything myself, building turbo kits, removing the motor, changing clutches, suspension work, wiring. Pretty much everything bar from Tuning a car (which should always be left to someone who has had experience) and cracking apart the motor.

Do you guys think its a possibility to replace the rings myself. My unk has an engine rebuilding shop so i will take it to him if i get stuck. But i would like to do it myself. I have the tools and the shed space and i will get some advice off him but i just wanted to know cos a few people on here would have done it.

Also what would be rough time it would take to complete by myself? I know theres ways of getting around it by not taking out the whole motor and just removing the bottom end and doing it that way. What would be the easiest way?

-

if you can jack it up enough to get under it, just remove the head and the sump, removing the sump will allow you to undo the big ends and then just push the pistons up through the bare block, replace the rings, then drop the pistons back in (properly of course) and do the big ends back up.

to see all of my build, checkout

-

However, if your cylinder walls are scratched you may need to get them honed which is always recommended when installing new piston rings to ensure they seal properly.

-

Originally Posted by FastFwd

Ok so i went to go pick up my civic from the tuners today and was told that my rings need replacing before taking it anywhere close to 20psi

Only rebuilt my motor roughly 20 thou ago. The previous tune must have chewed them up over a year. So i mean i've stopped mechanics working on my car for over 3 years now. I've done everything myself, building turbo kits, removing the motor, changing clutches, suspension work, wiring. Pretty much everything bar from Tuning a car (which should always be left to someone who has had experience) and cracking apart the motor.

Do you guys think its a possibility to replace the rings myself. My unk has an engine rebuilding shop so i will take it to him if i get stuck. But i would like to do it myself. I have the tools and the shed space and i will get some advice off him but i just wanted to know cos a few people on here would have done it.

Also what would be rough time it would take to complete by myself? I know theres ways of getting around it by not taking out the whole motor and just removing the bottom end and doing it that way. What would be the easiest way?

If you were willing to suffer the downtime from doing everything yourself (usually much longer than when done professionally) it's not so much the mechanical work it's that if something needs to be machined/honed/bored (as trism mentioned) or you need to oversize the cylinders and you initially buy the incorrect products...It can be a costly, prolonged and annoying process...

-

Originally Posted by ZeForce

However, if your cylinder walls are scratched you may need to get them honed which is always recommended when installing new piston rings to ensure they seal properly.

I dont think this should be a problem Zeforce, well i hope not. The engine is running fine, its just blowing a little smoke occasionally. We could have pushed the engine upto 12-15psi safely but the tuner said the engine would only last 6 months that way. I would like to correct this issue now so i dont cause a bigger problem later.

We have set the car with a clean tune to run upto 7psi atm but im just going to drive it like a nanna until i replace the rings

-

Originally Posted by Sp00ny

If you were willing to suffer the downtime from doing everything yourself (usually much longer than when done professionally) it's not so much the mechanical work it's that if something needs to be machined/honed/bored (as trism mentioned) or you need to oversize the cylinders and you initially buy the incorrect products...It can be a costly, prolonged and annoying process...

As i was saying to Zeforce, i hope there is no issue with the bores, the car runs completely fine atm so i mean its not actually in to bad shape. the car could perfectly run NA for another 100 thou. But trying to boost it up or over 20psi with the rings i have atm is just not gonna happen.

I will have to speak with my uncle about the bore size etc on the pistons we installed in the last rebuild because they are slightly oversized and de-compressive.

I think if i find anything wrong with the bores ill bolt it back up and remove the motor chuck it on the ute and drive it to my uncles to get the bores honed etc and done properly. But in saying that i will probably pull apart my engine bay and shave everything and hide my wiring and get the engine bay resprayed. I was going to do that in the last rebuild but i couldnt be stuffed.

Last edited by FastFwd; 05-04-2009 at 01:56 AM.

-

-

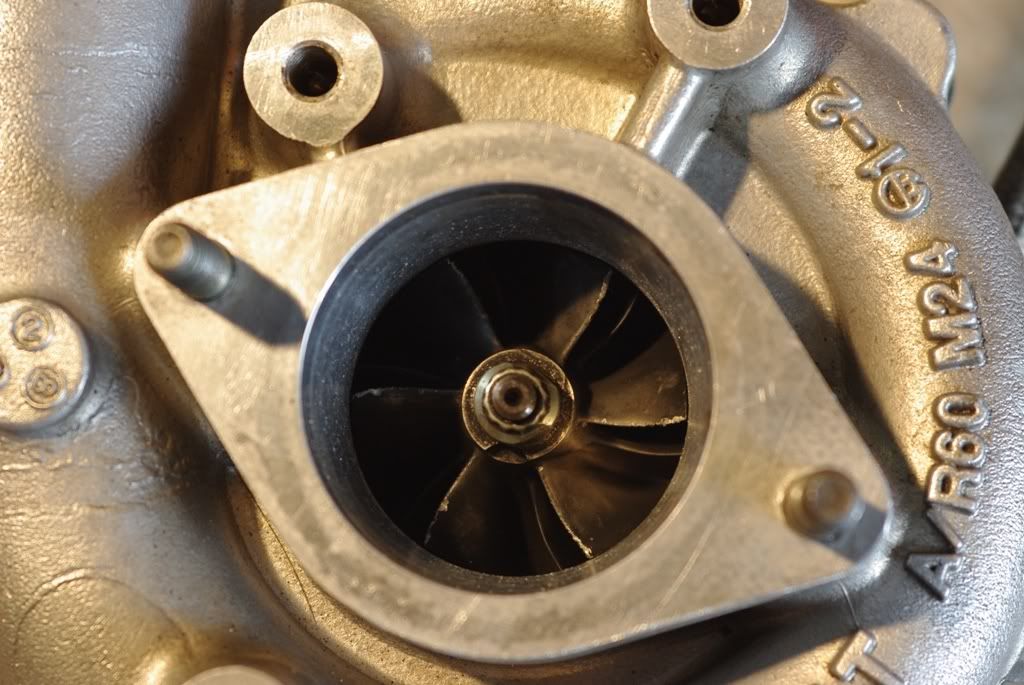

1. Get the turbo rebuilt, otherwise source a second hand one. Won't cost much more for either option.

2. Provided you've roughed the surface up before you painted it with some wet and dry, the paint will hold, especially if its the hi-temp paint (which it is).

3. You can buy stud removal bits from bunnings. Buy one that's a good/appropriate size for that stud you need removed. It's got a reverse drill tread so it grabs on to the sides when you turn it counter clockwise. Drill a 10-20mm hole in the stud and use it as such to take it out. Shouldn't be too hard...Did you take it off while it was still hot? Or was it overtightened? Looks like you've stripped the top bolt a bit as well.

-

Originally Posted by hayashi_1986

1. Get the turbo rebuilt, otherwise source a second hand one. Won't cost much more for either option.

2. Provided you've roughed the surface up before you painted it with some wet and dry, the paint will hold, especially if its the hi-temp paint (which it is).

3. You can buy stud removal bits from bunnings. Buy one that's a good/appropriate size for that stud you need removed. It's got a reverse drill tread so it grabs on to the sides when you turn it counter clockwise. Drill a 10-20mm hole in the stud and use it as such to take it out. Shouldn't be too hard...Did you take it off while it was still hot? Or was it overtightened? Looks like you've stripped the top bolt a bit as well.

I probably wont buy another second hand turbo, I will probably repair the gt28. Anyone know rough prices on rebuilds?

Yeh i didnt rough up the surface so i will give that a try tomorrow and let you know how i go.

The stud has been snapped off like that since i got the exhaust shop to fix an old exhaust manifold i had. I didnt realise it was broken until over a year later so it was to late.

-

also if anyone know what upgrades i can do to my turbo like changing exhaust housings etc to get my turbo to run upto or over 400hp could you let me know.

-

3. What you're looking for is an "easy-out". They can be brittle though and exhaust bolts have a habit of being stuck in hard so be sure to clean out the threads really well and use plenty of WD40.

-

All i can recommend with 'easy outs', is dont get a cheap one. They will just break time and time again. Definately one tool you dont want to cheap out on if you want to get that stud out of there.

However, as above, it will likely be stuck hard in the head, so your best option might be to get it removed by a mobile thread repair guy while the head is off.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

Reply With Quote

Reply With Quote

Bookmarks