|

-

[Discussion] Wheel Spacers.... Different types, pros and cons, safety, and legality

After a talk with dean (DLO01), I thought I might start this thread and hopefully it will be beneficial to those who are wary and uncertain of using spacers.

It seems some people throw around the word 'spacer' far too often these days without understanding what is involved when choosing a spacer. With wheel offset and fitment becoming more and more in 'vogue' so to speak, the use of a spacer is becoming more common. However, the correct application of a spacer is still a bit of a dark area, with some people simply thinking that all spacers are dangerous and should be avoided at all costs. This is most definitely the case when a spacer is incorrectly specced to match the car and wheels. But spacers are perfectly safe when used correctly.

Ideally, you should buy a set of wheels that suits the fitment and brake clearance you are after without using a spacer, however this is sometimes not possible and spacers must be used.

However, it is not as simple as throwing on a spacer and calling it a day. There are 4 main types of spacer - Floating Slip on, Hubcentric Slip on, Floating bolt on, and Hubcentric Bolt on.

1. Floating slip on

These are commonly found in smaller sizes of 3 and 5mm, and are generally used when dealing with brake and suspension clearance issues when room is tight. Without using a floating spacer, your wheel nut will have a certain number of turns before it is tight. This number of turns decreases when a spacer is used due to the reduction of the amount of stud that is avialable for the nut to 'grab'. For this reason, it is recommended that extended studs be used with floating spacers. Extended studs require open ended nuts, so factor the cost of these into your decision. With these small spacers, you can get away with using your oem studs, however it is recommended that you use steel nuts as they are stronger than aftermarket alloy nuts - and when you have less stud to play with, the strength of the nut is very important.

As a general rule of thumb, you should not go any bigger than 5mm with floating spacers. As they are NOT hubcentric, the bigger the spacer, the bigger the leaver arm (distance away from the hub), and therefore the bigger the moment of force (torque) applied on the studs/hub. If you require a slip on spacer greater than 5mm, you should look into a hubcentric slip on spacer.

2. Hubcentric slip on

These spacers commonly come in sizes of 5mm and above, and are made to suit your specific application. They work on the same principle as a floating spacer, however they have a centrebore that matches the car's hub size, and a lip on the outer edge of the spacer that matches the centre bore of the wheel that you may be using. This assists with centering the wheel on the hub. As the size of a hubcentric slip on spacer will generally be 5mm and above, extended studs are essential to ensure your nuts actually hold your wheels on. Again, factor in the cost of open ended wheel nuts.

Spacers like these can be ordered from places like wheelworx (http://wheelworx.com.au/spacers.html). You will need to give them 4 measurements:

- Your Car's PCD

- The width of spacer you require

- Your Car's hub size

- Your wheel's centrebore size

They will then machine the spacer up for you.

3. Floating bolt on

Moving on from slip on spacers, we have bolt on spacers. These work by using your original studs to bolt the spacer onto the hub. The spacer then has 'new' studs which the wheel bolts on to. This eliminates the need extended studs and open ended nuts. Bolt on spacers can also be used to change PCD - by going from 4x100 -> 4x114.3, or 5x100 -> 5x114.3 etc.

If you want to reuse your wheel nuts, you need to make sure the studs on the spacer are the same pitch as your oem wheel studs. Hondas are 12x1.5, Nissans are 12x1.25 etc.

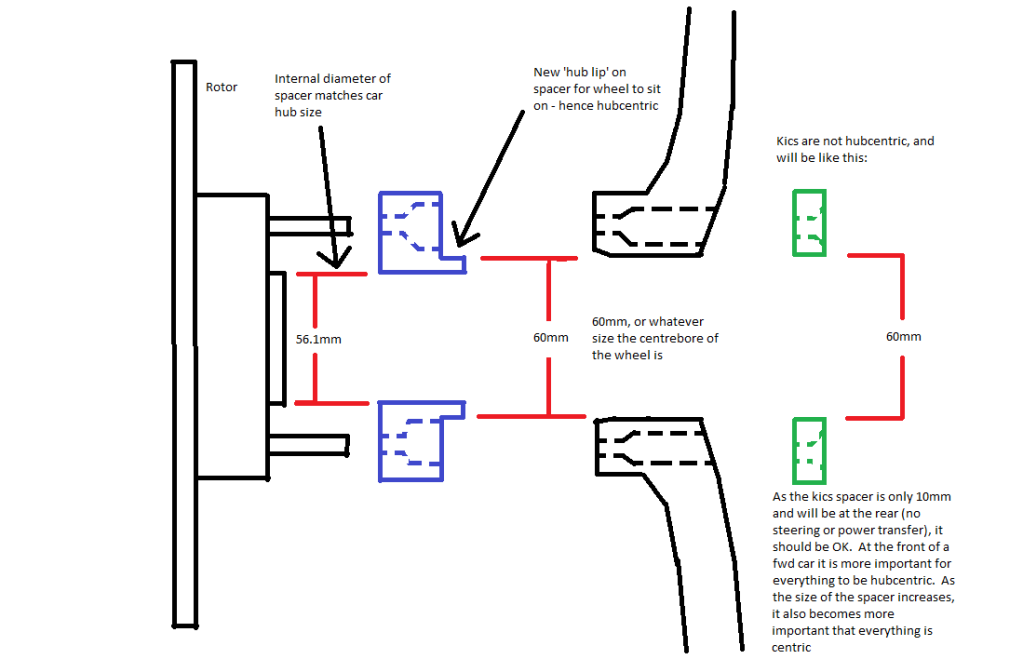

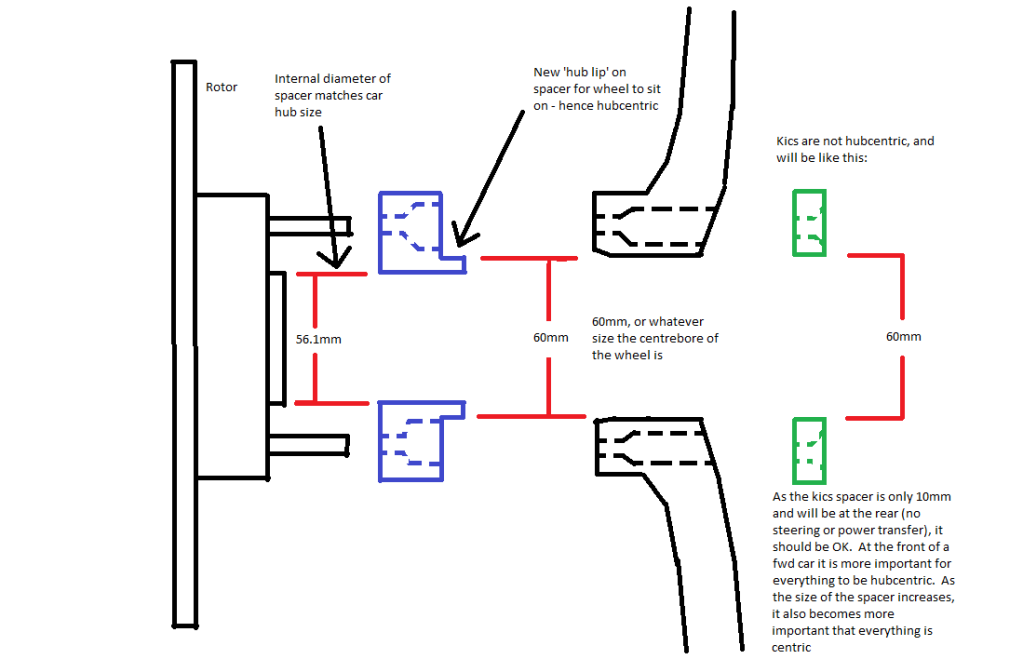

The floating bolt on spacers pictured above are project kics, and are not hubcentric - as you can see as the spacer has no lip for the wheel to centre itself on.

Before choosing a bolt on spacer, it is important to see if they will be compatible with your wheels. Ill just quote this from another thread.

Originally Posted by Alexx

There are many things to consider when buying spacers. Those spacers will bolt on to Eg5 hubs fine. However, this doesn't mean the wheels will fit on the spacer.

The studs from the car will stick out of the spacer, especially with a 10mm spacer (which is pretty small). Lets say the stock studs are 30mm. This means that 20mm of the stock studs will still be sticking out of the spacer. Many wheels don't accommodate that kind of room.

Some wheels have holes between the pcd holes specifically to provide room for the standard studs to sit when using a bolt on spacer. Others dont.

Some wheels might not have these holes, but have a section of the hub area cut out, others dont.

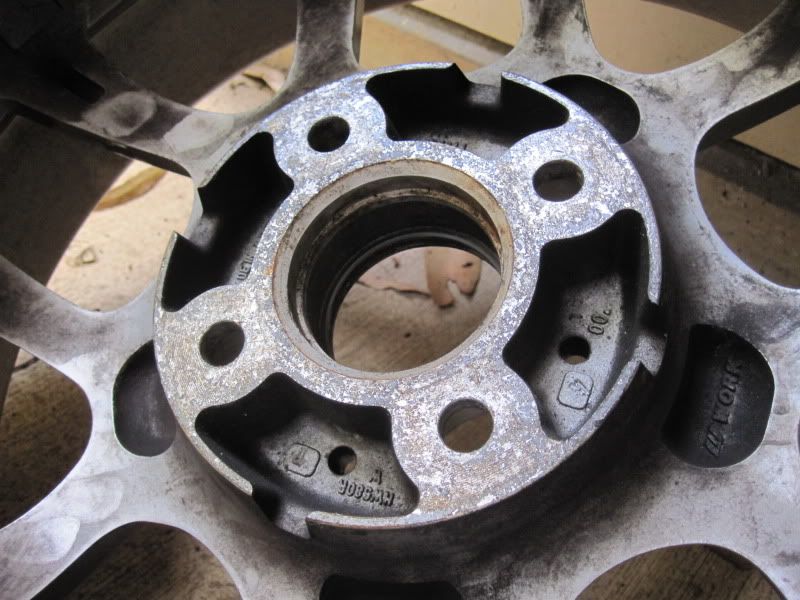

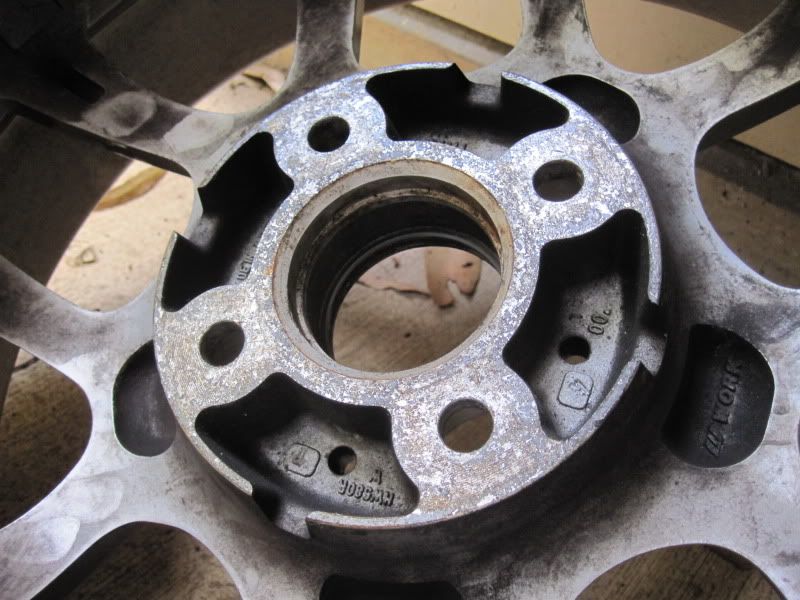

Pictures probably explain this best. For example: we are looking for room behind these wheels to determine if a bolt on spacer will fit.

With these wheels, that 10mm bolt on spacer will not fit. As you can see, there is no room for the stock studs to sit behind the wheel.

However, They will fit with these wheels. You can see there is provisions behind the hub for the studs to sit. Both wheels have holes that go through the wheel for the standard studs to sit when using a bolt on spacer.

This is why wheels like CPR have the extra 4 holes between the lug holes. Its to accommodate a spacer.

Some people put a bolt on spacer on their stock studs, then cut the stock studs so they can fit any wheel. This is NOT recommended - it will mess up the threads on your studs, and if you do finally get wheels that are the correct size and offset for an aggressive stance without a spacer you will have to get new studs.

Check your wheels first before buying a spacer.

So once you have checked to see if your studs will clear your wheels, you can go ahead and get a floating bolt on spacer. These should be kept to minimal sizes, ie 10mm. Any larger and you should be looking into getting a hubcentric bolt on spacer.

Floating bolt on spacers CAN be turned into hubcentric bolt on spacers, you just need the right centering ring. for example here:

4. Hubcentric Bolt on

Finally, we come to hubcentric bolt on spacers. These are to be used on larger spacers, anything over 10-15mm. Again, you should first check to see if your wheels will clear the oem studs.

As with hubcentric slip on spacers, machining shops can make these for you. Tell them your PCD, spacer width, thread pitch, hub size, and wheel centrebore size and they will whip it up for you.

The thread pitch of the studs needs to be the same if you want to reuse your wheel nuts.

I drew this up to help in another thread explaining how hubcentric bolt on spacers work compared with kics spacers:

Diagram isnt entirely accurate in terms of where the new studs go that come out of the spacer, but the principle remains the same, only so much you can do with paint  . .

Safety

This seems to be the most debated topic when discussing spacers. My opinion is that spacers are perfectly safe when appropriately specced to suit your car and wheels. Do the research and measurements and you will have no problems. But buy a generic 'hubcentric' bolt on spacer from ebay that has a completely different hub size to your car and you may have issues.

Legality

As far as i am aware, the use of a spacer is Illegal. It is up to you if you want to run the risk of being defected. However, as far as I am aware it is possible to get them engineered - A properly specced setup should pass easy if thats the case in your state. Someone please correct me if I'm wrong.

Please add anything I have missed  . .

Discuss

Last edited by Alexx; 02-08-2013 at 07:56 PM.

-

Awesome write up.

Someone rep the man.

--------------------------------------

PM's Turned Off

Prelude - Sold.

S2000 - Sold.

NSX - Sold.

F355 - Coming...

-

alot of usefull info

FFamily

instagram - chumdab

-

spacers are illegal in vic. said bob jane lol.

S P A M | W O R K S

With our special rotational tires, it will allow you to drive very fast. - JK Tyre

-

-

Great post! I have one issue with it however. You imply that when a wheel or spacer is hubcentric then the protruding part of the hub shares some of the load. This is generally not the case once the wheel nuts are properly tightened. The majority of the load from the wheel to the suspension/knuckle is carried through static friction between the hub face and the wheel mounting face and it is the clamping load of the properly torqued nuts that make sure that this friction is sufficient.

In order for the protruding hub area to carry any load with a hubcentric wheel placed on it the fit between the centrebore of the wheel and the outer diameter of the protrusion on the hub would have to be extremely tight, bordering on a press fit. This is not the case.

Wheels being hubcentric primarily aids in getting the wheel centred when mounting so this is particularly important when using spacers as there is greater potential for mounting the wheels off centre which can cause havoc. I don't believe that it is essential that aftermarket wheels be made hubcentric with the use of hubcentric rings however.

-

Originally Posted by chargeR

The majority of the load from the wheel to the suspension/knuckle is carried through static friction between the hub face and the wheel mounting face and it is the clamping load of the properly torqued nuts that make sure that this friction is sufficient.

In order for the protruding hub area to carry any load with a hubcentric wheel placed on it the fit between the centrebore of the wheel and the outer diameter of the protrusion on the hub would have to be extremely tight, bordering on a press fit. This is not the case.

Good addition, and an oversight on my part. Post was getting long and rambly, but I definitely missed this. Torquing both the spacer nuts and the wheel nuts correctly becomes even more important when using a spacer

Originally Posted by chargeR

Wheels being hubcentric primarily aids in getting the wheel centred when mounting so this is particularly important when using spacers as there is greater potential for mounting the wheels off centre which can cause havoc. I don't believe that it is essential that aftermarket wheels be made hubcentric with the use of hubcentric rings however.

We had similar issues to what you describe at a track day in the past with an e30 running 20mm bolt on spacers up front. The spacers had been off while some work was done and were replaced without centering rings on the outer spacer lip to suit the wheels. Driving around on the street it wasnt noticeable, but the car had almost violent steering feedback at 140kph+, and was basically undrivable, due to the wheels not being centered 100%. Simple part wasted a whole day.

-

Ive killed a wheel bearing by the suspected use of 15mm kics bolt on spacers on my fd1.

That 15mm although it may seem negligant, does result in a larger moment about the bearing and hence loads it up more.

My advice is that if you are going to be using spacers (especially for daily driving over track work) then make sure you stay vigilant in tightening them up every couple hundred km's.

The reason is that if they do come loose for some reason, every time you go over a small bump/turn/etc you will start to shock load the bearing (which it isnt designed to cope with) and other componants within that general system.

Having said that, I do like the extra track width that spacers provide you with but after my head ache I don't think I will be going back.

Just my 2 cents.

2012 BMW S1000rr - 184whp, 9.733s @ 148.27mph - Quick enough!

2006 Honda Civic - 101whp, 61s BBGL Short - When I need a bbt.

-

Originally Posted by ludecrs

Awesome write up.

Someone rep the man.

Done already!!

Alexx has always helped me with tyre/wheel questions,he knows his stuff real good,great to see this thread and the sharing of that knowledge mate!

-

-

Thanks for the clarification.

-

been running 15mm spacer at the front and 10mm spacer at the rear for over a year now, no drama's here so far

using h&r hub centric spacers along with arp studs and appropriate wheel nuts for oem or aftermarket wheels

Tags for this Thread

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|

.

.

Reply With Quote

Reply With Quote

Bookmarks